EMIT Lab

The EMIT lab’s mission (Engineering Materials for Transformative Technologies) is to conduct advanced manufacturing research aimed at lowering the carbon footprint, primarily in the aerospace, automobile, and energy industries. This will be achieved by increasing the material and energy efficiency of manufacturing processes, improving operational efficiency during the product’s use phase, and enabling transformative technologies such as nuclear fusion, high-efficiency turbine systems, and rocket engines.

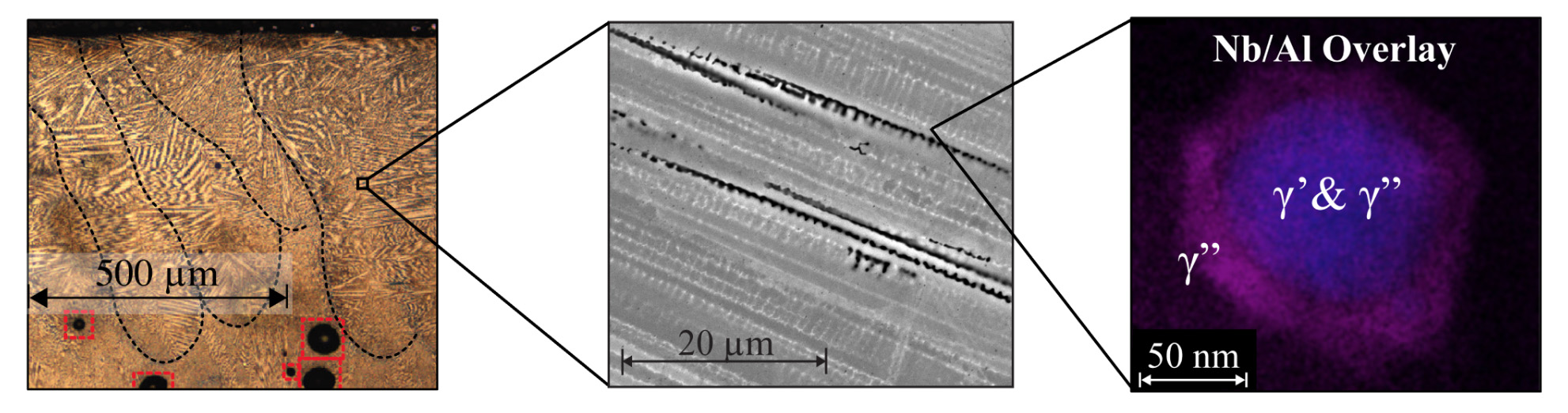

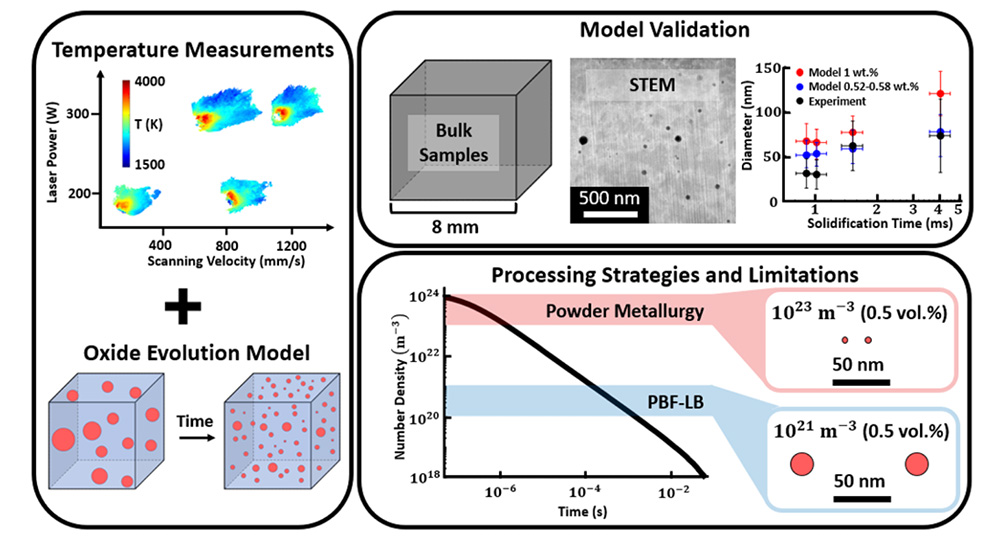

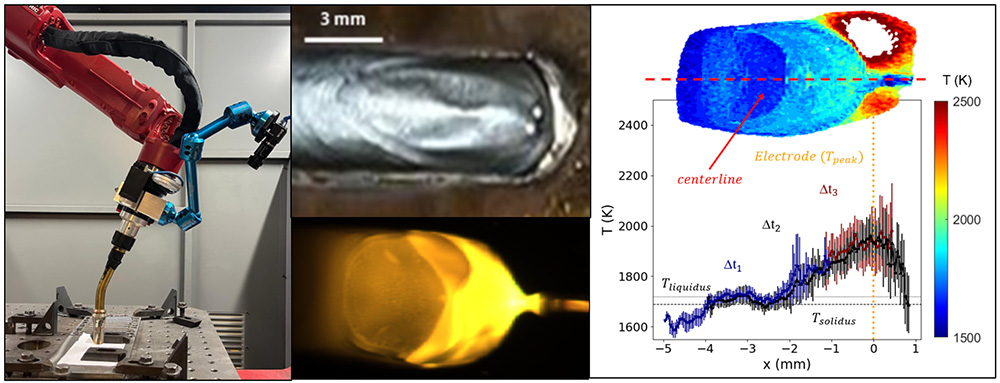

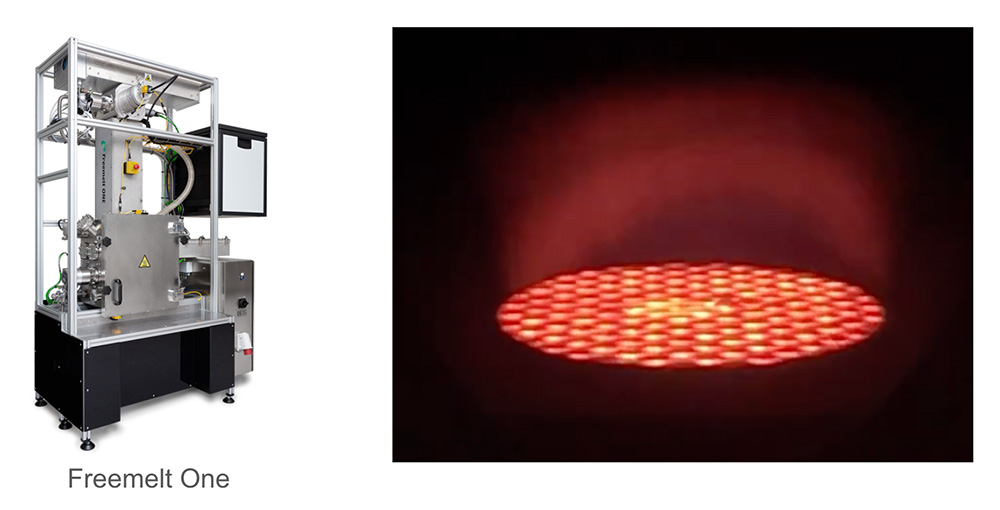

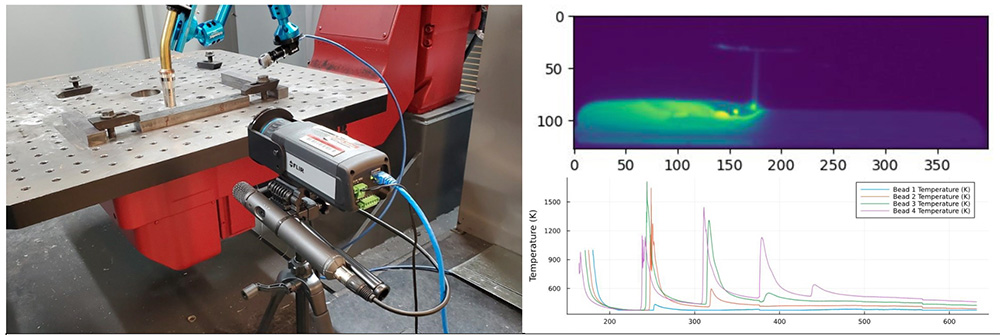

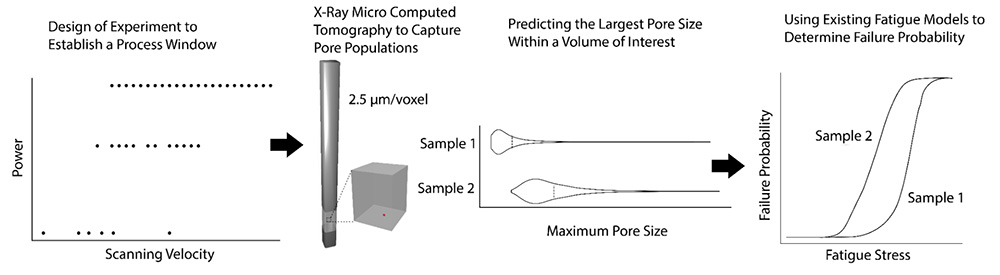

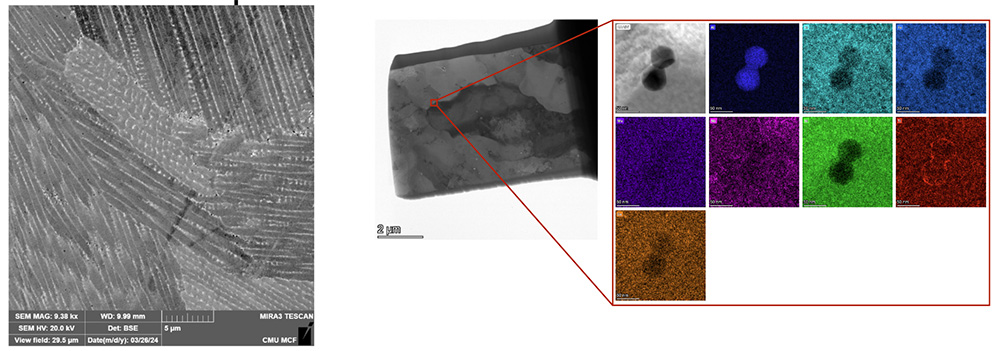

Towards this mission, our primary focus is on developing a deeper understanding of process-structure-property relationships through both physics-based and statistical modeling, as well as multiscale and multimodal characterization. This knowledge is applied across our metal additive manufacturing projects to develop strategies for real-time monitoring, process optimization, and control, with the goal of creating adaptable, high-quality metal manufacturing processes for improved part performance and consistency.